Grain Handling and Storage - A Hedt Family History

by Brian Hedt

This is a history of grain handling and storage, on-farm, as it applies to Hedt family history… In 1948 my father Lou (38 years old) bought 838 acres at Blackheath North of Horsham Victoria for £12.10 per acre. The family moved there in July. It became a “bumper” season.

Due to starvation in Europe, the wheat price went up to £25/ton that year, c/w. £19/ton in 1947 and 1949. Handling charges were about £2.10/ton. The basic wage was £7.10 per week, but averaged £9 to £10.

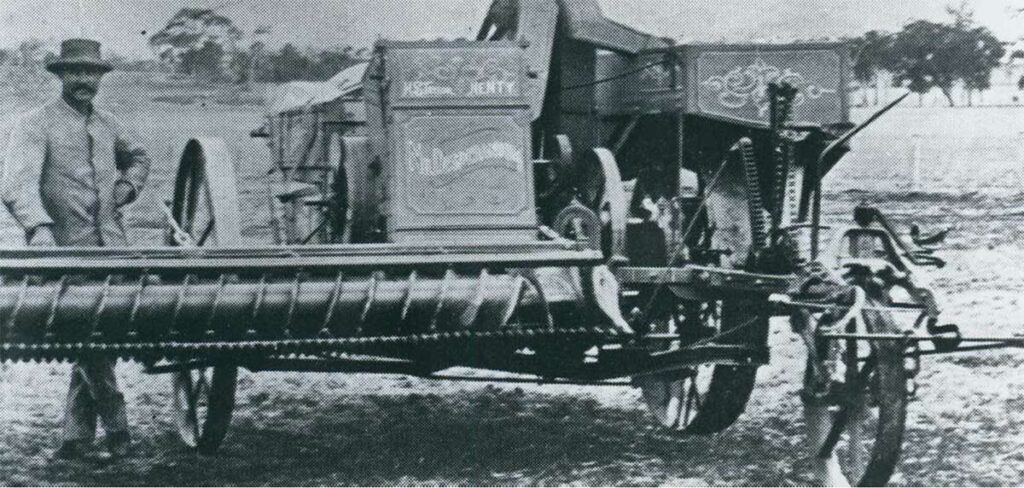

He harvested 600 acres of wheat including share farming on Nuske’s (on west side of Wimmera River) and approximately 300 acres at Antwerp. It all averaged about 30 bu/acre. Stripped with HST 10 ft header (see pic) with a grain box auger that had to be hand turned to allow more wheat in. Lou’s shoulder swelled up so much his Dr. said he needed 6 weeks rest but Lou had a harvest to gather! Lou said he’d never handle bags again and ordered a “Rodda” billy cart and portable auger ( made in Geelong) in 1949 making him one of the very first farmers in the district to move from bags to “bulk handling” of grain verses the traditional method of bagging every bushel.

Because this and the following harvest was so big he was also the first farmer to dump his grain on the ground in bulk, building a “bunker” style enclosure with fence posts and corrugated iron. My eldest brother Max, then only 14 years old helped auger and shovel this grain into dad’s new Rodda auger and into dad’s Morris “Commercial” truck with a 200+ bushel bulk bin on it.

We used this style of in-field grain handling and storage right through into the early 1970’s.

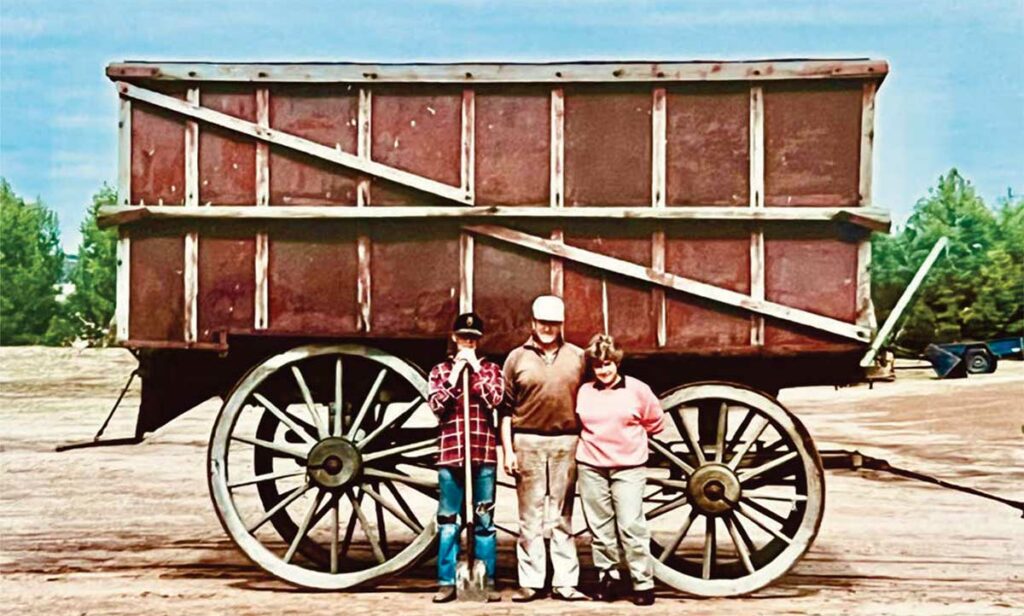

In 1952 my father and a neighbor built a mobile bulk storage of sheet metal and timber on his disused German table-top wagon. This was used by me until 1974 for grain handling and storage.

In the early 1960’s my brother Max built 3 of these 1000 bushel bins. They are effectively a forerunner of today’s 4000-6000 bushel mother bins. They included a unique PTO driven auger, a double universal in the auger bend, slide gates to control grain flow, wheels that jacked up and down for transportation and a manually operated swivelling spout. Later a unique 2-way roof was added that allowed filling from both sides.

In the early 1970’s these 800-1000 bushel light weight towable field bins had become very popular and although mother bins have superior attributes these bins are still manufactured today. Many farmers have 6 to 10 or more of these in use during harvest. Many of these old bins are now used in farm yards for seed and fertilizer storage. We never liked these because of the labor intensive nature of moving them.

Our 1983 mother bin with a capacity of about 2000 bushels.

… And today our son David has introduced the North American farmer to his 4000+ Walkabout Mother Bin continuing a 75 year history of innovation over 3 generations and on two continents.